Cable Quality Quirks

By far, the most frequently asked question we get is, "Is this a good quality cable?", along with its follow-up question, "How do I know that this is a good quality cable?" In this article, we will attempt to offer some general guidelines for examining cable quality; we will also debunk some popular quality myths.

If you open a dictionary, you'll find several definitions for the word "quality." Generally speaking, though, it is understood that a "good quality" cable is one that:

- is well-constructed, so that it will not break during normal (or even above-normal) usage

- does the job that it has been designed to do

So, the quality of a cable is a measurement of the extent that a cable does or does not satisfy those two requirements.

Unfortunately, determining if a cable is a "good quality" cable using the two tests above can be tricky, for several reasons. Although it is often easy to tell if a cable is built poorly, it is not necessarily easy to know if a cable is built well; even worse, a cable that appears to be well-constructed may still not be properly designed or engineered for the task it is supposed to perform. However, the other extreme also exists; there are cables that are over-engineered, with features that do nothing to enable the cable to perform.

To make matters worse, there are very few general guidelines that apply to all cables, as different cables have different constructions, different materials, and different manufacturing processes, and traits that are desirable in one type of cable may be completely inappropriate for another type. Having said that, in terms of a cable being "well-constructed", there are some general things to look for in almost any cable.

First and foremost, the place to look for signs of trouble with a cable is generally not along the length of the wire, but rather, the workmanship at the connectors, since 95% or more cable failures occur at the connector. Depending on the specific cable, most manufactured (as opposed to hand-made) cables have what is known as a "strain relief", which is a molded, slightly flexible section of the wire where it attaches to the cable.

|

|

|

Comparison of two cables with and without strain relief |

|

Its purpose is two-fold: first, it helps anchor the connector to the wire, and second, it helps prevent the wire from bending too sharply (for example, at a sharp 90 degree angle) when it leaves the connector (hence the name "strain relief"). You will want to look for a strain relief that is firmly secured ("molded") to the connector, with no visible seams, cracks, or separation from the connector.

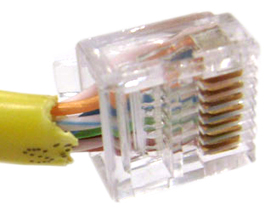

Some cables, by their very nature, make it easy for you to view the workmanship at the connector; certain telephone and network cables fall into this group, as well as some audio / video cables (such as certain RCA cables). When possible, examine the workmanship for clean cuts, clean solder connections (rarely visible), straight flushed connectors, etc.

|

|

|

|

| Examples of Strain Relief | |||

Unfortunately, the vast majority of quality sins are committed in such a way as to make it difficult to see them. Such blatant examples as the yellow network cable below are rarely (though sometimes) seen in public. But most quality shortcuts are found inside the cable, where they won't be seen if you don't have the luxury of being able to cut the cable open.

So how can you protect yourself? One way is to ask the supplier for a technical drawing of the cable. This is a drawing that will detail the quantity and type materials used in the construction of that cable. Although sometimes very technical in nature and difficult for the lay person to understand, the fact that a supplier is willing to offer its drawings for public scrutiny generally speaks volumes about the supplier's commitment to quality. Among the interesting things you can learn from cable drawings are:

- The material used in the wire conductors (copper, copper-clad steel, silver, etc)

- The type of shielding present in the cable (and thus, it�s effectiveness)

- The jacket (and other insulating) material used (which can affect electical performance)

- The rated electrical performance of the cable (this information varies in relevance from one cable type to the next)

It is always good to be a little skeptical of sellers who tout quality features that can't explain exactly what the benefit of that "feature" is. It is also good to be skeptical of suppliers that will describe their cables in broad terms, but are unable or unwilling to provide detailed specifications on their products.

|

|

| Poorly Made Network Cable | High Quality RCA Cable |

Common Quality Myths

Below are some of the most popular myths surrounding cable quality.

-

Myth #1: Thicker is better

We've all heard this one, "This is a nice, thick cable. It must be good quality." Unfortunately, the apparent thickness of a cable really has very little to do with the quality of the cable. To a certain extent, it is true that thicker copper wires can generally carry a given signal (or electrical load) a little further than thinner wires, this is only true to a point. And a "thick cable" does not necessarily mean that the wires inside are any thicker; we've seen any number of "thick cables" with thin wires inside and thick outer jackets, giving a deceptive appearance without providing any benefit. Even when a particular cable is constructed with thicker wires, that is not always a guarantee that the signal quality will be any better. -

Myth #2: Better materials means better quality

Most people are surprised to see this one on a list of myths. After all, common sense would clearly indicate that if you use better materials, you get a better quality cable, right?

To a point, this is somewhat true. It is certainly true that poor quality materials can yield a poor quality cable. However, there is a point where, once the cable is doing what it is supposed to do, additional workmanship, better materials, or more "features" really do nothing to further improve the performance of the cable. Some manufacturers love to tout various "features" of their cables, features which, while certainly impressive-sounding, actually do nothing to improve the performance of a cable. One example that we often cite is silver-coated wires on a six-foot HDMI cable. Yes, it is certainly true that silver is a very fine conductor of electricity, but on a short cable like that, it offers no performance benefit over traditional copper-based cables. -

Myth #3: A High-quality cable can "improve" performance

This is a myth perpetuated by consumers and manufacturers alike. They claim that a high quality cable will "improve" the signal of whatever device it is connected to. This is nonsense. Just as a chain is only as good as its weakest link, a cable can only transmit whatever it receives from the device. It cannot "improve" or "clean up" any data coming in to it.

This myth probably gets reinforced because customers will buy a high-quality cable, plug it in, and see improvement. What this means is that the previous cable was not doing its job, and was degrading the signal. What the customer is now seeing is simply what he or she should have been seeing all along.

In spite of this, there are manufacturers who will claim that their cable can improve the performance of a system. Some even go as far as to claim that their product will "clean up" a bad signal. Steer clear of these products; good cable engineering principles dictate that a cable should do one thing and only one thing: deliver the signal that it received, intact and without modification, to the other end.

(Note: there is one exception to this rule, but it is not a cable. Power surge protectors *do* have built-in electronics that allow them to "clean up" surges / spikes and electromagnetic interference that are commonplace in household electricity.)