Cables are, of course, a fundamental component of wired networks. Their efficacy highly influences network connection and data transmission. Over time, manufacturers have evolved wires to be more durable and resistant to interference. It’s important to note that even the most proficient cables have their vulnerabilities. CableWholesale explores the common causes of cable failure so you can make the most informed choices when selecting and installing cords for your wired network setup.

Insulation Damage

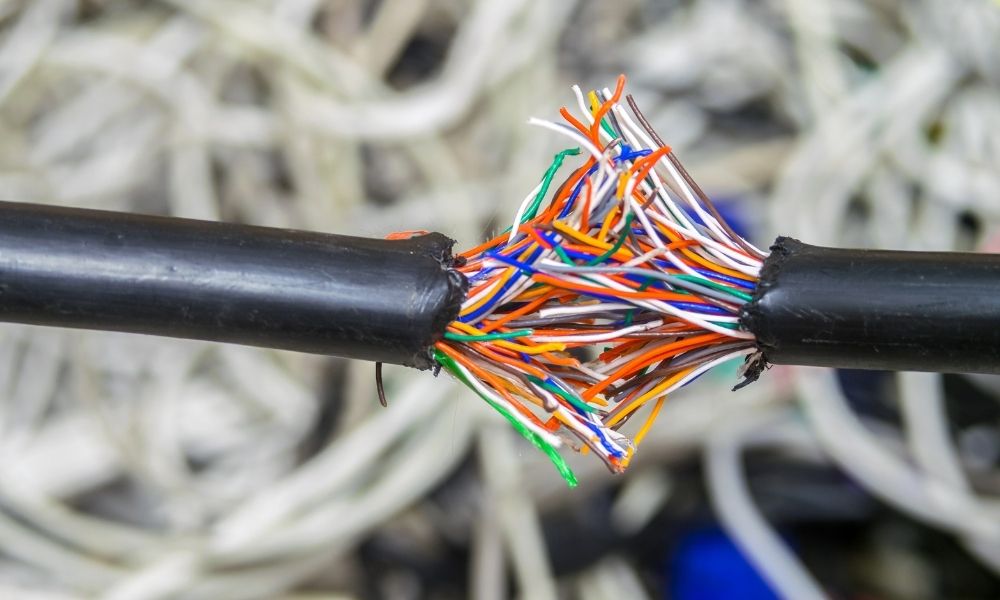

Conductors are necessary for electric signal transference. When the quality of the conductors inside your cable is compromised, it’s known as insulation damage. Insulation damage is usually caused by:

- Bending stress

- Abrasion within the cable structure

- Conductor strand breakage

Continuity Loss

Copper conductors are susceptible to breaking, just as any other conductors are. Copper conductors can sever under increased flexing pressure, during which the cable core can’t absorb the mechanical load. A loss of continuity occurs when insulated conductors are twisted with the wrong pitch length or direction.

Corkscrewing

Corkscrewing is one of the most identifiable common causes of cable failure. Also known as the “pigtail” effect because of its appearance, the corkscrew condition occurs in a cable when torsional forces are released during operation. Reasons that forces may release include the following:

- Incorrect cable configuration

- Wrong pitch length

- Wrong pitch direction

Layered cables, rather than bundled cables, are more prone to corkscrewing.

Jacket Abrasion, Swelling, Or Cracking

A compromised cable jacket can be the pitfall of any wired network. The jacket is a protective layer that shields wires from electromagnetic interference and damage. The softer the jacket, the more susceptible the underlying layer of conductors or shielding will be to wear and tear.

Jacket swelling and cracking are additional issues that can cause cable failure. Cable jackets will swell when in contact with oils or chemicals they cannot withstand. Cracking is often the result of extreme temperatures—the jacket breaks and deteriorates down to the cable’s shield.

Running cables outside makes them highly vulnerable to abrasion and cracking from external elements. If you need to arrange an outdoor network setup, be sure to opt for durable outdoor Ethernet cables and other robust IT gear.