How To Make An Ethernet Patch Cable

This month we're going to show you how to make your own ethernet patch

cable!

The two main choices you will encounter when choosing an ethernet cable is

whether you would like to use Cat5e or Cat6. The chief difference is going to

be the bandwidth of each cable. Cat6 cables have the ability to transfer a

larger amount of data than Cat5e cables. This doesn't necessarily mean it

always makes sense to choose Cat6. In fact for home networks it may make more

sense to choose Cat5e cables. Also you probably won't need the extra

bandwidth Cat6 provides at home. Cat6 is fantastic for commercial settings,

larger networks, and for high-end multimedia set-ups.

Another important note is that while making a DIY patch cable is a

rewarding experience for general home or office use it may make more sense to

purchase pre-terminated patch cables. Please view this article for

information and learning purposes and not as the best way to obtain a patch

cable.

While we understand at first glance this may seem like a daunting task

it's actually quite straight-forward. All it takes is the right tools,

patience, and the willingness to learn. So let's get started!

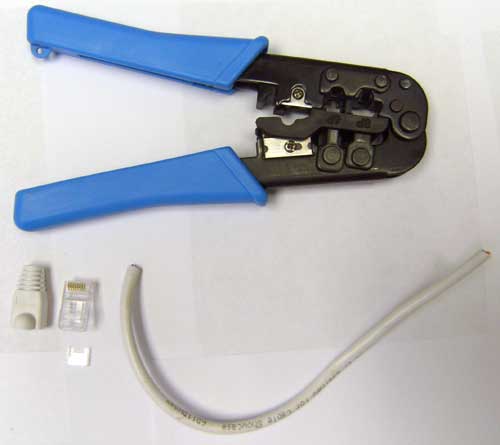

Tools and Parts you Will Need:

- Cat5e or Cat6 Cable: Bulk Cable

- Cat5e or Cat6 Crimp Connectors with or without Insert: Crimp Connectors

- Crimp Tool: Part: 91D5-56800

- Strain-Relief Boot: Strain-Relief Boots

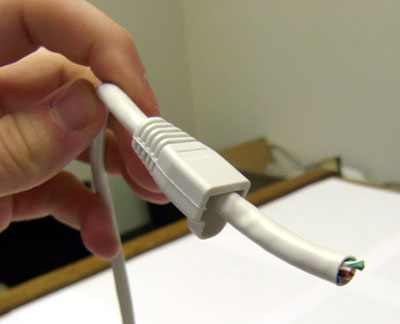

Step 1: Slide on the Strain-Relief Boot

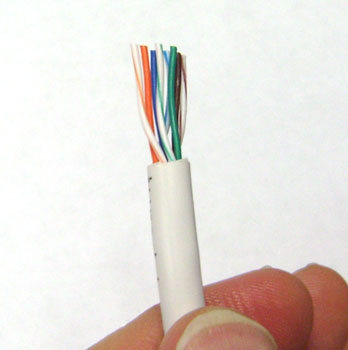

Step 2: Stripping the Outer Jacket

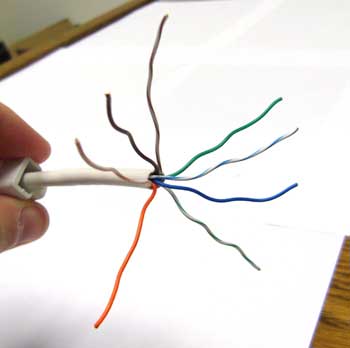

Step 3: Organizing and Lining Up the Wires

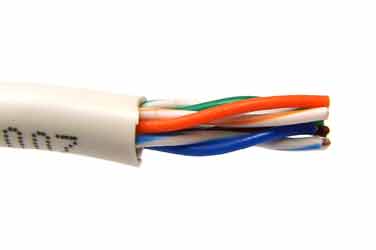

We're going to use the T568B standard. This standard uses the color order:

- Orange/White

- Orange

- Green/White

- Blue

- Blue/White

- Green

- Brown/White

- Brown

When creating patch cable wiring,it's a good idea to untwist the wires as little as possible; just enough that the wires can be sorted out. You will have to straighten out each cable so that it lines up neatly next to each other. The goal is to have the 8 cables lined up next to each other and also straight enough to be easy to manage.

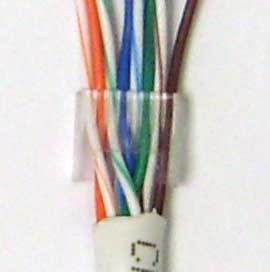

Step 4a: Cutting the Wires and Applying the Holder (With Insert)

Step 4b: Cutting the Wires (Without Insert)

Step 5: Trimming the Cable and Slipping the Connector on the Cable

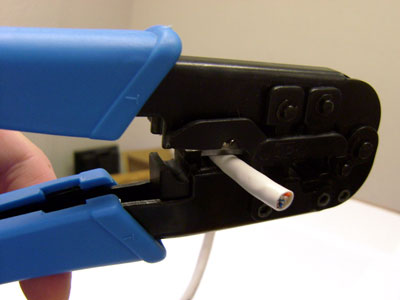

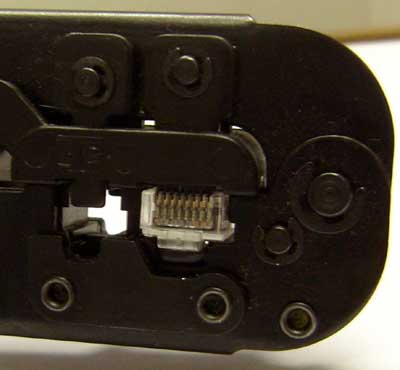

Step 6: Crimping the Connector

The pressure you apply on the crimper will be applied to the pins as there are 8 tiny metal prongs in the crimper that apply pressure to each of the 8 conductors on your cable. The pins in the connector are then pressed down into contact with the 8 copper wires of the cable creating a connection.

Make sure you squeeze the crimper all the way down to ensure a connection.

The Finished Cable

And there you have it, a completed DIY Ethernet patch cable!

As an option there are cable testers available such as our NetTestE tool, which can help test the cable after it's made.